No Till

What Do I Need To Look For In A No Till Or Minimum Tillage Planter?

For a no till or minimum tillage operation, all the farmer needs is:

– A No till seeder, a boom spray of multiple widths and a low horsepower tractor.

– Weed control via chemicals is assisted by harvesting water into the seedbed.

– Applications of seed and fertiliser / gas can be made in firm ground in one pass.

See separate comprehensive information sheet.

Lets have a look at what you must have and how the Multiplanter fulfils those requirements. We will also identify what you need to watch out for to ensure you get what you need.

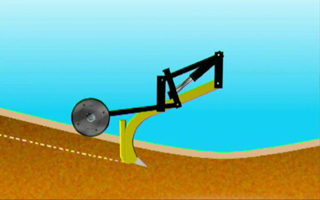

- Must have. Depth controlled seed tubes. The Multiplanter tine is parallelogram controlled by the press wheel.Look out for. If the seed tube is mounted to the tine, and the tine isn't independent to the frame, it can't be precision depth, even if it has its own press wheel. It is being depth controlled by the wheels on the frame.

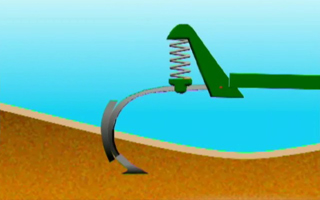

- Must have. Narrow 50mm (2") speartip with wings, and a 15 degree soil entry angle for minimal soil disturbance.Look out for. Steep soil entry angles that bust the soil up and out of the trench. Discs alone do not provide a seed bed.

- Must have. Hydraulic pressure, a small 50mm (2") speartip and C shaped tine that pulls itself in at a 15 degree angle. The Multiplanter is able to vary pressure on tines from the tractor cab on the run.Look out for. Springs can't be adjusted on the run. Watch out for hydraulics that have fixed pressure and can't be adjusted from the cab on the run.

- Must have. The depth of the digging tip controlled. Multiplanter press wheels control the depth of each individual digging dig, so there are even trenches over undulating country, with limited bulldozing or skimming.Look out for. Uncontrolled digging tips, where there will be skimming and bulldozing.

- Must have. The ability to pull extremely wide machines with smaller tractors. At normal depths, a D11 will be able to pull a 65m (302ft) Multiplanter with 273 tines at 4hp per tine.Look out for. Digging tip fixed to the frame and not depth controlled.

- Must have. High 840mm (33") underframe clearance, C shaped tine, large wheels fore and aft, minimum of 333mm (13 1/3") rows to allow trash to roll through.Look out for. Wheels inside the frame and straight tynes. Low underframe clearance, with narrow row spacings.

- Must have. The Multiplanter has the ability to plant into subsoil moisture down to 230mm (9") deep.Look out for. Planters that can't vary the depth of the seed placement. Operations will be limited to good planting seasons only.

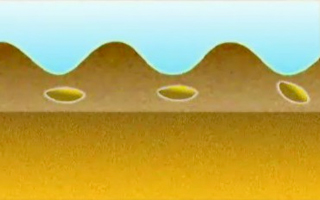

- Must have. The ability to channel water directly to the crop and deprive weeds on the mound of moisture.Look out for. Press wheels that are wider than the tip, they will not be able to penetrate the trench. Discs do not allow for collection of water.

- Must have. Multiplanters have little wear and maintenance. Demonstrated is the wear of a 19 year old bolt from a parallelogram pivot point. There is no opportunity to wear when the tine is under hydraulic pressure.Look out for. Disc machines, machines with lots of grease points and castings, parallelogram tines not under pressure, tips without adequate long life protection and pneumatic press wheels that will puncture.

- Must have. Accurate seed placement, planted at speed, and placed at the bottom of the trench.Look out for. Smaller row spacings that throw soil into the adjacent seedbed, compromising depth.

- Must have. The ability to plant shallow, compact each seed in moist soil, so that every seed can come up, quickly and evenly.Look out for. Gangs of press wheels, not individual press wheels. They won't follow each individual tine and pressure under them may be uncontrolled.

- Must have. Large 18" (460mm) diameter semi pneumatic. Wedge for sandy soils, flat for all other soil types. Less revolutions means longer bearing life, semi pneumatic smear less than solid rubber.Look out for. Pneumatics puncture too often. Small diameter press wheels are a maintenance problem and battle to turn in rough country.

- Must have. The ability to set the breakout to whatever level is desired. The Multiplanter tine and press wheel come up in unison (renovator tine shown). Slow hydraulic release after compression.Look out for. Springs which get stronger as they compress. Torque transference causes premature metal fatigue.